Advancement in Self-Healing Asphalt Technology for Sustainable Road Infrastructure

Self-healing asphalt is a pavement material capable of automatically repairing micro-damages, such as cracks caused by traffic loads and environmental influences. This technology is developed to extend the lifespan of roads, reduce maintenance costs, and enhance infrastructure sustainability. By utilizing the natural ability of bitumen to heal itself along with additional technologies such as induction heating and rejuvenator microcapsules, self-healing asphalt can restore the strength and integrity of roads without requiring major repairs.

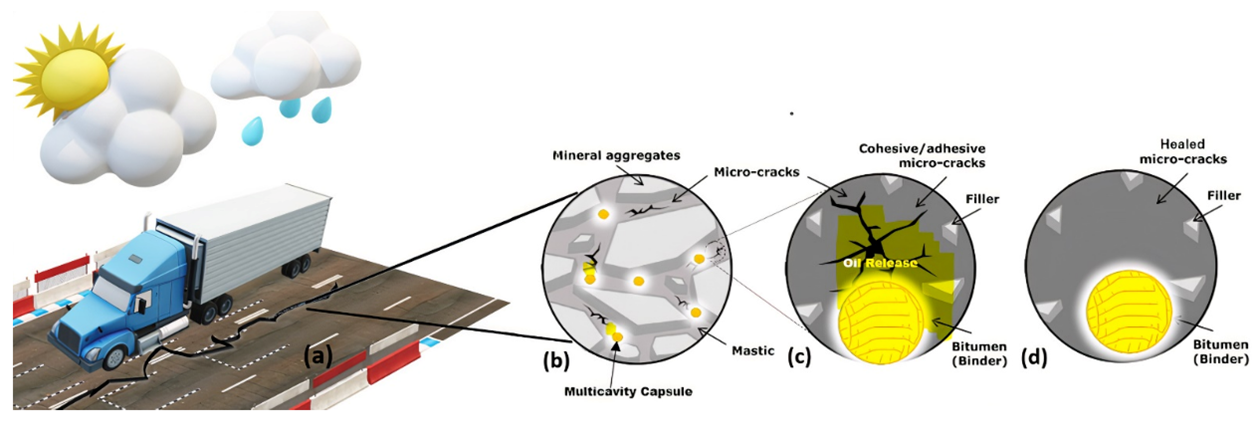

Self-healing asphalt with capsules releasing oil to seal micro-cracks.

Self-healing asphalt with capsules releasing oil to seal micro-cracks.

The main mechanism of self-healing asphalt is based on the viscoelastic properties of bitumen. When microcracks occur on the surface or structure of the asphalt, bitumen molecules can diffuse and fill the gaps during rest periods or at certain temperatures. This process can be accelerated by external heating methods (induction or microwave), which soften the bitumen so that the cracks can close again. Internal factors affecting this process include the type of bitumen, aggregate, mixture gradation, and the content of additional materials such as steel wool or metal slag. Meanwhile, external factors include ambient temperature, rest time, humidity, and the degree of material aging due to UV exposure, freeze-thaw cycles, and chemical pollution.

There are two main technologies that support self-healing asphalt: induction heating and the use of rejuvenator microcapsules. In the induction heating method, conductive particles such as steel wool are mixed into the asphalt. When an electromagnetic field is applied, these particles generate heat that softens the bitumen around the cracks, accelerating the healing process. Additionally, the use of electric arc furnace slag (EAFS) as a substitute for natural aggregate has been proven to improve the healing efficiency and mechanical properties of the asphalt mixture, while also supporting sustainability principles by utilizing industrial waste. Rejuvenator microcapsules rupture when cracks form, restoring the flexibility and cohesion of the bitumen.

Self-healing asphalt offers various benefits, such as extending road lifespan, reducing maintenance costs, and minimizing the use of new materials, thereby supporting infrastructure sustainability. The faster repair process also reduces traffic disruptions and carbon emissions from heavy equipment. However, challenges in implementing this technology include optimizing the content of additional materials such as steel wool and EAFS, developing standardized testing methods, and the decline in healing effectiveness after several heating or healing cycles. Moreover, initial production costs and the need for specialized equipment for induction heating remain considerations for widespread adoption.

Moving forward, the development of self-healing asphalt still requires extensive further research to optimize material composition and heating methods for greater efficiency and cost-effectiveness. The use of recycled materials and industrial waste such as EAFS can be further enhanced to support the principles of a circular economy and environmental conservation. Furthermore, performance validation in the field and long-term testing are crucial to ensure the effectiveness of this technology under various environmental conditions and traffic loads. With technological advancements and interdisciplinary collaboration, self-healing asphalt has the potential to become the new standard in building longer-lasting, cost-efficient, and environmentally friendly roads.

References

Mahmoud, A. A., Shafik, C. G., Elshahat, M. R., & Mostafa, A. E. A. (2024). Producing self-healing asphalt pavement mixture using induction and microwave heating. Trends in Advanced Sciences and Technology, 1(1), Article 8.

Varma, R., Balieu, R., & Kringos, N. (2021). A state-of-the-art review on self-healing in asphalt materials: Mechanical testing and analysis approaches. Construction and Building Materials, 310, 125197.

Comments :